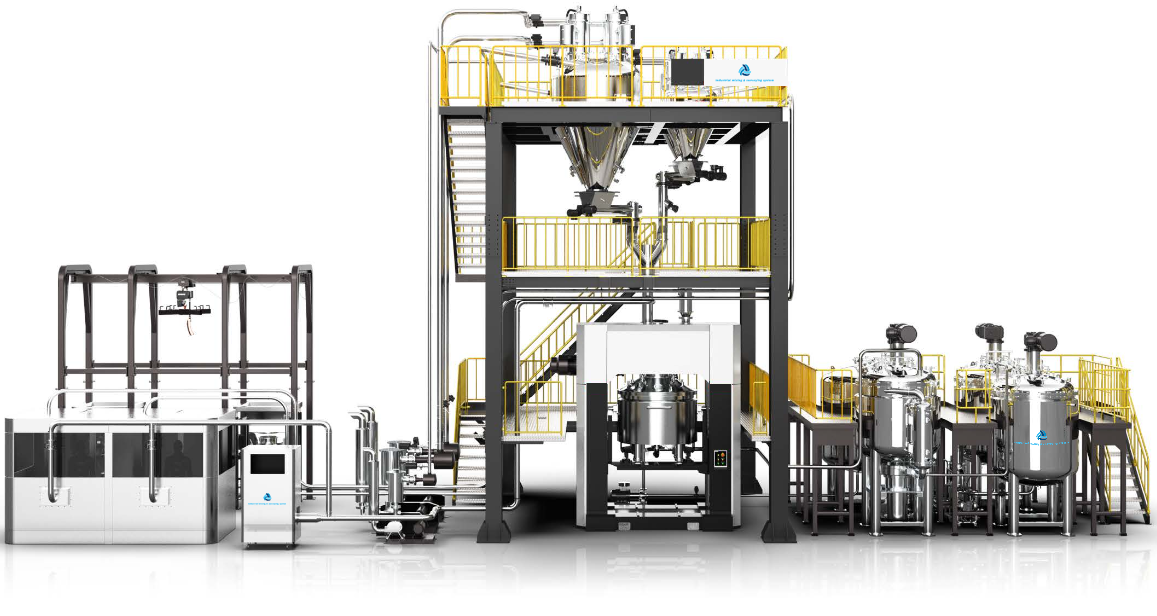

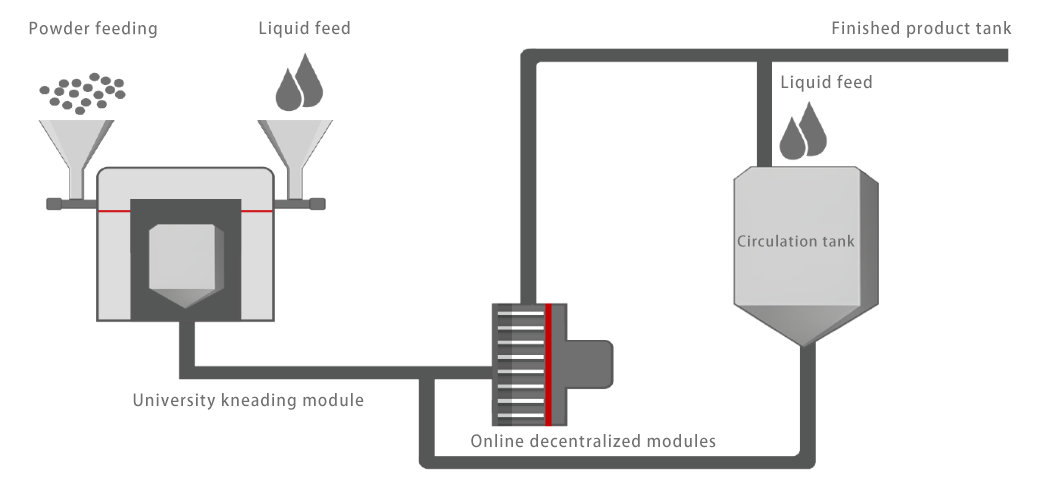

This integrated design combines high-efficiency kneading with high-speed dispersion, employing a unique high-viscosity kneading and online dispersion process. This approach significantly enhances the solid content of positive and negative electrode slurry, dramatically reducing production costs of lithium battery and representing a crucial advancement in lithium battery slurry mixing technology.