Regardless of the industry, we can provide you with professional solutions, not limited to the following industries.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

The cantilever planetary mixer is a high-efficiency mixing equipment that integrates vacuum low-speed mixing and high-speed dispersion. It combines revolution and rotation to achieve full mixing of materials. It can be used in the mixing process of various solvents and powders, such as the batching process of raw materials such as lithium-ion batteries, tapes, solar energy, and chemicals. The equipment has an integrated design, good mixing uniformity, and is convenient and easy to use.

Gantry mixer is a highly efficient and multi-purpose equipment that integrates reaction, mixing, kneading and dispersion. It is suitable for production processes of liquid-liquid, solid-liquid, paste-paste, powder-paste and other materials with different densities and proportions, from low viscosity to high viscosity (1.5 million Cps) in various industries.

The core equipment of this system is used for the mixed dispersion of nanomaterials such as positive and negative electrode slurries of lithium-ion batteries, CNT slurries, carbon nanotube slurries, Ketjen black slurries, and alumina slurries.

This intermediate transfer tank has a capacity range from 20 liters to 2000 liters. All parts in contact with materials are made of SUS304 stainless steel, ensuring durability and hygiene.

The glue mixer is a professional mixing and dispersing equipment for glue, adhesive and other materials, with a capacity range of 20 liters to 2000 liters. The part in contact with the material is made of SUS304 stainless steel to ensure corrosion resistance and easy cleaning.

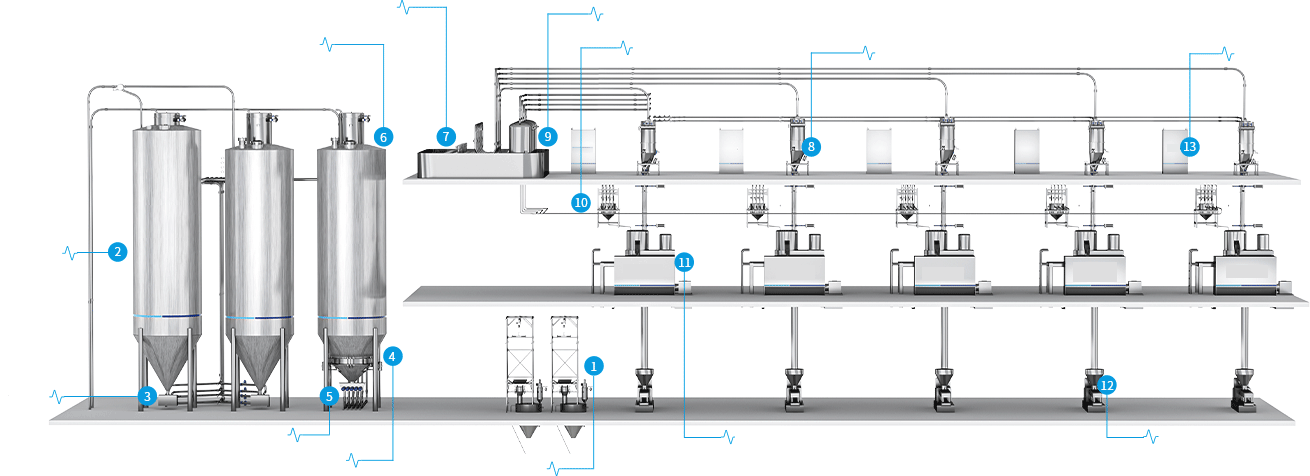

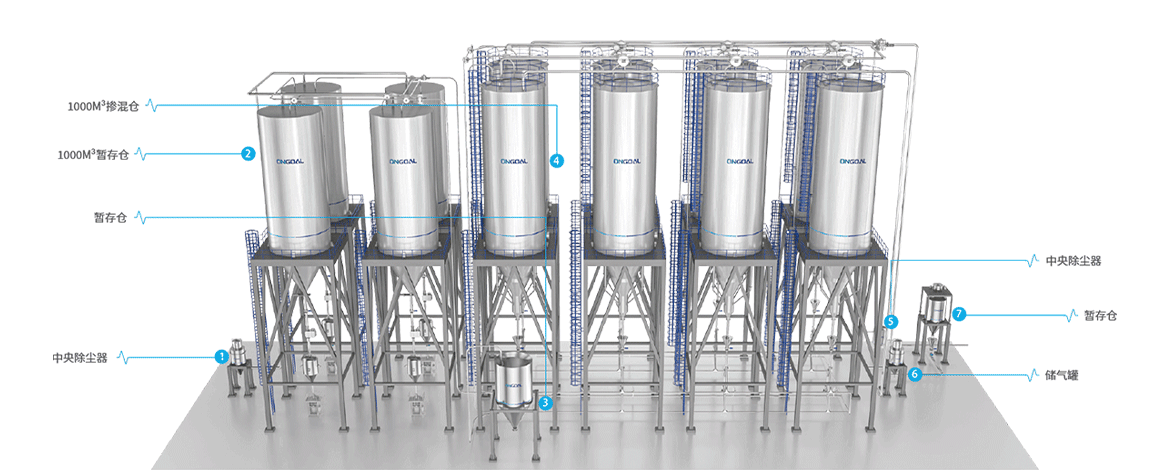

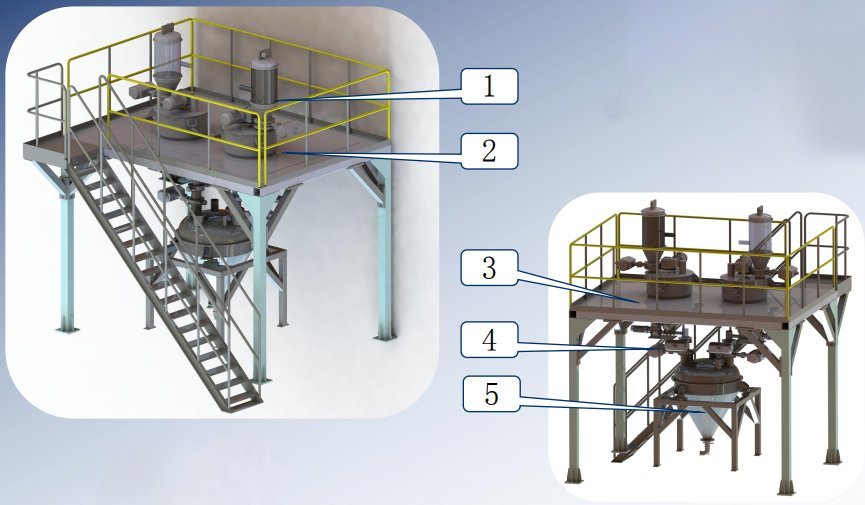

Automatic metering and conveying of powder materials. The powder materials enter the silo through the pipeline valve under negative pressure. The entire silo is placed on a weighing sensor. A screw conveying device is installed at the bottom of the silo. The materials are accurately measured by weight loss and enter the lower secondary metering tank. After entering the secondary metering tank, the materials enter each mixer from the secondary metering tank. The material is conveyed and measured.

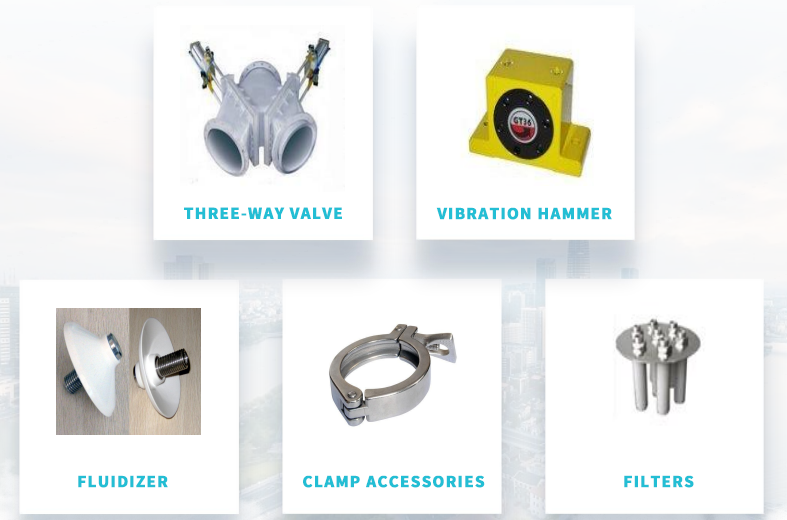

Core accessories:

1. Powder conveyor

2. Silo (primary metering tank)

3. Conveying screw

4. Weighing system

5. Silo (secondary metering tank)

Choose accessories according to your needs

We are a company dedicated to the development and production of industrial mixers, with a strong focus on homogenization systems. Through years of practical experience and numerous successful cases, our equipment has gained wide recognition in the market. Our mixing solutions excel not only in the new energy industry but also have significant market potential in powder transportation, pharmaceuticals, food, chemicals, and plastics. We are committed to continuous technological innovation to meet the diverse needs of various industries, providing our customers with efficient and reliable solutions.

Uhotting © 2024. All Rights Reserved.

Your email information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!