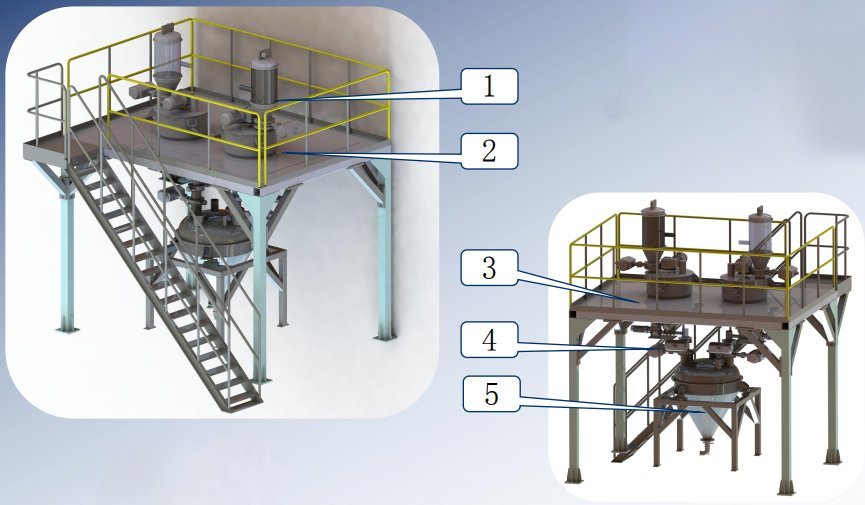

Cyclic High-efficiency slurry Mixing System

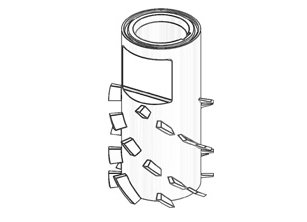

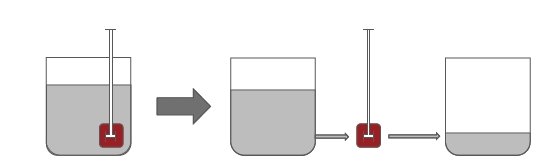

The core of the circulating efficient pulping system is to integrate powder/liquid premixing and fine dispersion in one machine, which can quickly complete the preparation of high-quality battery slurry. In this system, the powder agglomerates are first broken into smoke by the breaking head. Under the vacuum generated by the Venturi effect, the powder is quickly wetted by the annular “liquid curtain” generated by centrifugation to complete the premixing. The premixed slurry passes through the narrow gap between the rotor and the stator to obtain dispersion under high shear rate. Thanks to the high-flow circulation method, the whole batch of materials can be dispersed multiple times in a very short time to obtain the finished slurry.